As we near the end of 2019, let’s take a look back at another notable field start-up this year: Mariner. Norwegian national operator Equinor brought the Mariner oil field onstream in the UK on August 15th, 2019. The ultra-heavy oil field was originally discovered by Unocal in 1981 and it took a further 31 years before the operator at the time (Statoil acquired the field in 2007 and subsequently re-branded the company as Equinor) would move forward with a $7.7 billion final investment decision late in 2012. The field is expected to produce at a plateau rate of 55,000 bopd and to be operational for 30 years, producing some 300 million barrels of oil from a reserve base of 3 billion barrels.

“Mariner is one of our most innovative offshore developments, and Equinor is at the forefront of applying new digital solutions and the latest technologies. We are testing new ground through our offshore digital workers, automated drilling and the use of Echo, a digital copy of the platform, to deliver safe and efficient solutions.” - Equinor, August 2019

Automation… Digitalisation… Efficient Solutions. Comforting words to hear, surely, for any oil company CFO or investor when so much emphasis since 2015 has been placed on capital discipline. Somewhat less comforting, perhaps, for those involved in the offshore supply-chain and associated logistics provision.

With the application of technology, how does that change the role for people? What does the data tell us about such a state-of-the-art offshore field development? Air & Sea Analytics takes a closer look at Equinor’s Marnier project.

The reason the Mariner field lay undeveloped for so long is that heavy oil is difficult and often expensive to produce. It is highly viscous and requires additional energy to get it to the surface compared to light oils. Developing an ultra-heavy oilfield in one of the world’s harshest offshore operating environments is certainly no mean feat.

Oil has been described as the ‘lifeblood’ of many economies but the lifeblood of the oil industry itself is often overlooked when the statistics tend to focus on billions of dollars and million of barrels….. that lifeblood being people. In the case of Mariner, this clearly continues to be the case - hundreds of people working offshore, responsible for hooking up and commissioning equipment, drilling wells and preparing the facilities for first production.

So many people, in fact, that Equinor hired an accommodation vessel (the ‘Safe Boreas’) to moor alongside the main production platform ‘Mariner A’ and the high-spec jackup drilling rig ‘Noble Lloyd Noble’. Over 800 people at a time have been working on the hook-up phase prior to first production.

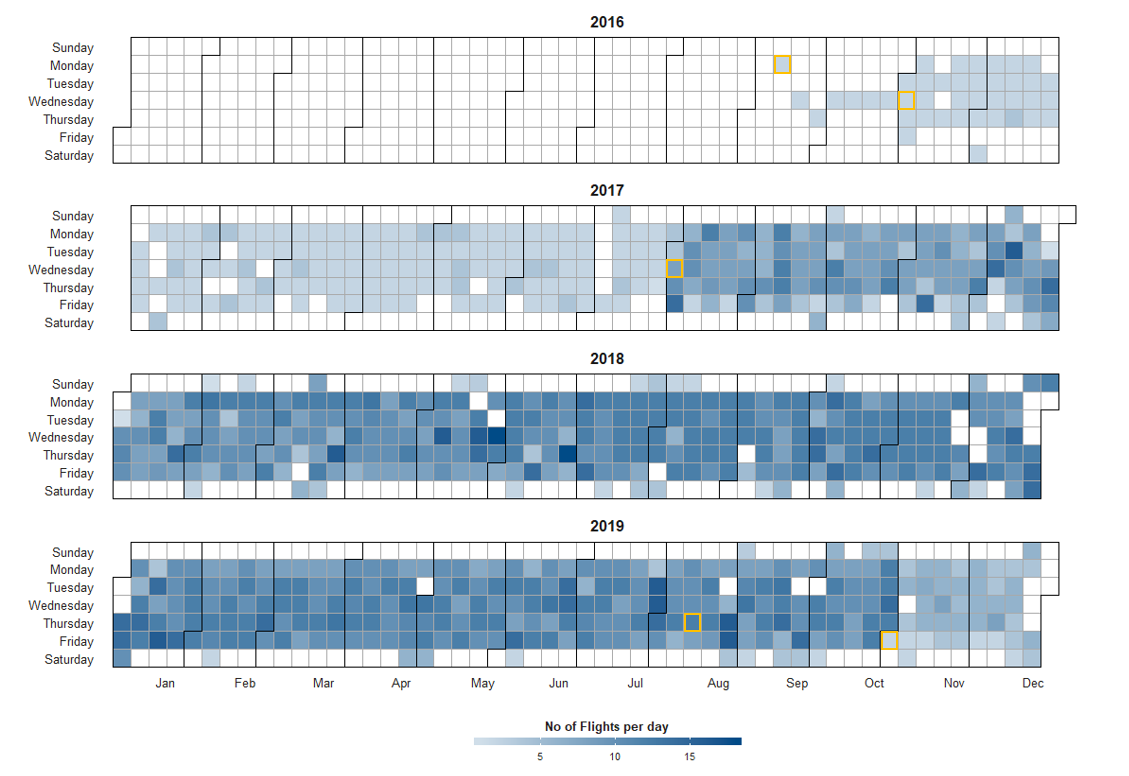

Analysis of helicopter flight data over this period show the remarkable volume of activity required to support the field development. A total of 5,712 flights were made in the field development phase prior to first oil.

The contract for Mariner’s helicopter services was awarded in June 2014 to CHC, requiring two Sikorsky S-92 aircraft for a term of five years with options to extend a further three years. The contract began in 2016 and flights started on the 12th September with CHC initially operating one S-92 as the only infrastructure at the field at the time was a steel jacket (with no topsides) and the ‘Mariner B’ floating storage unit with around 20 people on board. (dates highlighted below in yellow)

No .of flights per day to facilities at Mariner field centre. Milestones and arrival/departure of key infrastructure highlighted in yellow. Chart shows data to Dec 28, 2019.

The arrival of the Noble Lloyd Noble in November 2016 prompted a notable increase in flights, increasing in frequency from weekly to daily, as can be seen above. The drilling rig has been underway on Equinor’s programme of 50 wells and 92 sidetracks.

The Mariner A platform jacket (substructure) was installed in 2015 with the topside following in August 2017. The topside installation prompted the start of a very intensive period of activity, with as many as 16 helicopter arrivals and departures at the field location on the busiest days. On the 1st November 2019 the accommodation vessel ‘Safe Boreas’ left the field location and after a three day journey at sea arrived in port near Kristiansund in Norway. Flight activity to Mariner has subsequently dropped and is at the time of writing is two or three trips (4-6 flights) per day.

(The keen-eyed will note that no flights to the field have been recorded on Christmas day on any of the previous four 25th December dates. EASA rules require that from 7 June 2020, all aircraft that weigh more than 5,700 kg will require ADS-B transmitters to be fitted. Given that Father Christmas, his sleigh, nine reindeer and important payload are collectively likely to be above this threshold we should expect to see his annual flight recorded in the data from next year onwards.)

The S-92 has been a mainstay of North Sea operations and particularly in recently times as it has, since 2016, been the only ‘Heavy’ (>10,000kg MTOW) in operation in the region (with the absence of the H225), carrying up to 19 passengers at a time. Despite the global oil and gas downturn (and lack of new orders for Heavy helicopters) Sikorsky have continued to invest in the S-92, launching the ‘Rig Approach’ system in 2015 to offer an automated approach capability for the S-92 when operating at offshore platforms and rigs. In early 2019 Sikorsky also announced a new S-92 variant, the S-92B (or S-92A+ for retrofitted aircraft) with higher performance engine options, a new gearbox design, latest automation technology including ‘Rig Approach 2.0’ and new cabins that can be more-easily reconfigured between offshore and SAR roles.

Location of S-92 Fleet August 2017 (left) vs August 2019 (right).

Data from Air & Sea Analytics show a net ‘migration’ of S-92 units into the UK in recent years with 44 offshore S-92s in country, as activity has gradually recovered since the downturn. The UK has the highest number of offshore crew transfer S-92s in-situ. The Maritime and Coastguard Agency have a further 11 SAR (Search and Rescue) S-92s in the UK operated by Bristow.

What does the future hold? Some operators have publicly stated that they won’t pursue far-from-shore developments – in a Capex constrained environment they feel they just don’t need to, with easier to access opportunities nearer shore. Others however, including Equinor, continue to look to push the boundaries. An example is the Bay du Nord field, which lies some 450km offshore the east coast of Canada.

An Equinor employee noted that:

“Bay du Nord will require us to look at everything and really think about how we operate and service a platform so far from shore. The project is currently under evaluation and has to pass a number of decision gates before we get to FID.”

For now, at least, it seems that whilst the application of technology and innovation is yielding benefits in terms of safety, efficiency and costs – the need for world class people to deliver & operate world class oilfields has not gone away.

Steve Robertson, Director.

Air & Sea Analytics